Scientists Discover Potion of Steel Resilience Components

- Berkeley

VIVA – The scientists focused on studying the alloy CrMnFeCoNi (chromium, manganese, iron, cobalt, and nickel) after realizing that its strength increased at the temperature of liquid nitrogen without compromising toughness.

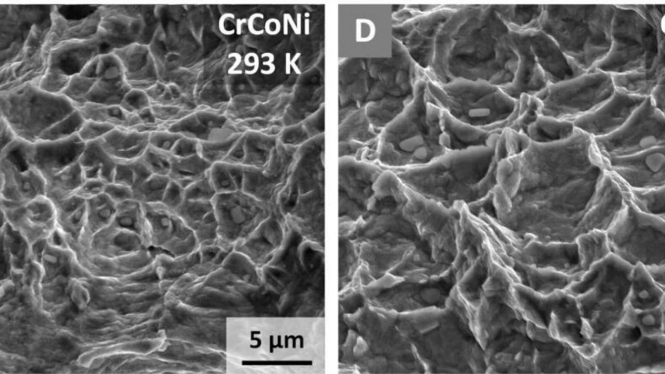

However, one of the derivatives of this alloy, CrCoNi, showed even more astonishing characteristics. Scientist has identified an alloy of cobalt, nickel, and chromium as the toughest one known.

The team led by researchers from the Lawrence Berkeley National Laboratory and Oak Ridge National Laboratory reported encouraging results regarding CrCoNi. All components of this material are mixed in equal proportions. This is a rare feature: alloys usually mix the constituents differently. But most importantly, the performance properties of this mix are unique.

“When you design structural materials, you want them to be strong but also ductile and resistant to fracture. Typically, it’s a compromise between these properties. But this material is both, and instead of becoming brittle at low temperatures, it gets tougher,” Easo George said.

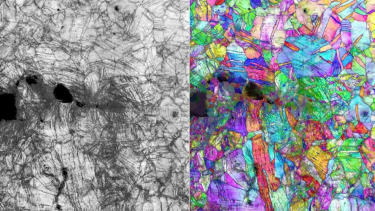

Gambar mikroskop dari deformasi struktur kristal.

- Berkeley

The alloy showed very high strength properties, which only increased with extreme cooling. The same “inadequate” behavior was shown by impact toughness parameters, deformation resistance, and ductility.

Steel, even its best varieties, becomes brittle in such circumstances, whereas the new material, on the contrary, only gets stronger.

“The toughness of this material near liquid helium temperatures (20 kelvin, -424 Fahrenheit) is as high as 500 megapascals square root meters. In the same units, the toughness of a piece of silicon is one, the aluminum airframe in passenger airplanes is about 35, and the toughness of some of the best steels is around 100. So, 500, it's a staggering number.” A scientist, Robert Richie stated.

The result of the newly created material is because when temperatures fall to critical levels, it fundamentally changes its crystalline lattice: from cubic to hexagonal.

This behavior of the atomic structure allows metals both to keep flowing and keep meeting new resistance from obstacles on a more immense level.

The material is unlikely to be used in everyday life, especially since cobalt and nickel are in short supply these days. But it is likely to become more widely used in the space industry and the production of equipment used in the Arctic.